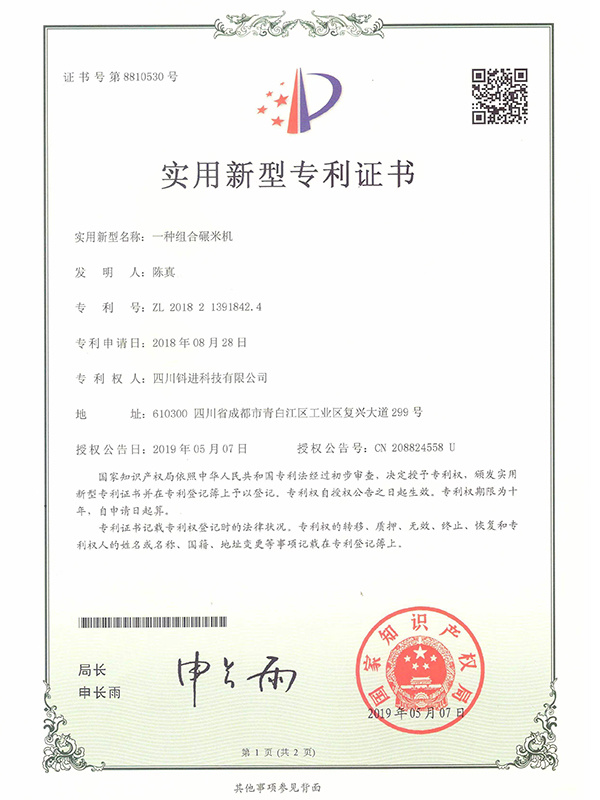

Patent of Rice milling shaft for rice milling chamber of combined rice mill machine

A rice milling shaft in the context of a combined rice milling machine refers to a central rotating component that plays a crucial role in the mechanical processing of rice during the milling operation. In rice milling, particularly in combined rice milling machines (which integrate several milling stages into one machine), the shaft serves as the backbone of the milling system, driving various parts of the machine through rotational motion. Here’s a breakdown of the functions and role of the rice milling shaft in the rice milling chamber: 1. Transmission of Power: The rice milling shaft is typically driven by an electric motor or engine. It transmits rotational power to other key components of the machine, such as the hulling chamber, polishing chamber, and separating units. The shaft helps drive different mechanical processes within the milling system, including grinding, friction, and separation. 2. Rotation of Milling Elements: The shaft is connected to various milling elements, such as rice rollers or hulling stones, which are responsible for removing the husk, polishing the rice, or sorting the grains. As the shaft rotates, it causes these components to move, grinding, crushing, or polishing the rice kernels. 3. Rice Milling Chamber: In the milling chamber, the rice is subjected to a combination of friction and pressure, which removes the outer layers of the rice (such as the husk and bran) to reveal the white rice kernel. The shaft helps to drive the movement of hulling rollers, which rub against the rice to separate the husk from the grain, and in some cases, it may also assist in polishing the rice to achieve a shiny finish. 4. Adjustable Milling Process: In some advanced combined rice mills, the milling shaft is designed with adjustable mechanisms to control the speed and force of milling. This allows for better management of rice quality, such as controlling the level of polishing or minimizing broken grains. 5. Efficient Grain Separation: The rice milling shaft can also drive screens or sieves that separate the husked rice from the non-husked rice, as well as separate broken rice from whole rice grains. This is a key function in ensuring the final product is uniform and of high quality. 6. Integration in Combined Milling Systems: Combined rice milling machines integrate several rice processing functions—such as dehusking, polishing, and grading—into a single machine. The shaft helps synchronize these processes, making the machine more efficient and reducing the need for multiple separate machines in a rice processing plant. Design and Durability: Since the rice milling shaft operates under continuous stress and friction, it is typically made from high-strength steel or other durable materials to withstand the mechanical forces involved in rice milling. It is also designed to have a long lifespan to ensure the reliability of the milling process. Conclusion: In a combined rice milling machine, the rice milling shaft is essential for transferring power and driving various milling components. It ensures that the different stages of milling—such as dehusking, polishing, and separating—occur smoothly and efficiently, ultimately producing high-quality rice ready for packaging and sale.

Classification:

Detailed introduction

A rice milling shaft in the context of a combined rice milling machine refers to a central rotating component that plays a crucial role in the mechanical processing of rice during the milling operation. In rice milling, particularly in combined rice milling machines (which integrate several milling stages into one machine), the shaft serves as the backbone of the milling system, driving various parts of the machine through rotational motion.

Here’s a breakdown of the functions and role of the rice milling shaft in the rice milling chamber:

1. Transmission of Power:

- The rice milling shaft is typically driven by an electric motor or engine. It transmits rotational power to other key components of the machine, such as the hulling chamber, polishing chamber, and separating units.

- The shaft helps drive different mechanical processes within the milling system, including grinding, friction, and separation.

2. Rotation of Milling Elements:

- The shaft is connected to various milling elements, such as rice rollers or hulling stones, which are responsible for removing the husk, polishing the rice, or sorting the grains.

- As the shaft rotates, it causes these components to move, grinding, crushing, or polishing the rice kernels.

3. Rice Milling Chamber:

- In the milling chamber, the rice is subjected to a combination of friction and pressure, which removes the outer layers of the rice (such as the husk and bran) to reveal the white rice kernel.

- The shaft helps to drive the movement of hulling rollers, which rub against the rice to separate the husk from the grain, and in some cases, it may also assist in polishing the rice to achieve a shiny finish.

4. Adjustable Milling Process:

- In some advanced combined rice mills, the milling shaft is designed with adjustable mechanisms to control the speed and force of milling. This allows for better management of rice quality, such as controlling the level of polishing or minimizing broken grains.

5. Efficient Grain Separation:

- The rice milling shaft can also drive screens or sieves that separate the husked rice from the non-husked rice, as well as separate broken rice from whole rice grains. This is a key function in ensuring the final product is uniform and of high quality.

6. Integration in Combined Milling Systems:

- Combined rice milling machines integrate several rice processing functions—such as dehusking, polishing, and grading—into a single machine. The shaft helps synchronize these processes, making the machine more efficient and reducing the need for multiple separate machines in a rice processing plant.

Design and Durability:

- Since the rice milling shaft operates under continuous stress and friction, it is typically made from high-strength steel or other durable materials to withstand the mechanical forces involved in rice milling. It is also designed to have a long lifespan to ensure the reliability of the milling process.

In a combined rice milling machine, the rice milling shaft is essential for transferring power and driving various milling components. It ensures that the different stages of milling—such as dehusking, polishing, and separating—occur smoothly and efficiently, ultimately producing high-quality rice ready for packaging and sale.

Previous:

Next:

Language

Language