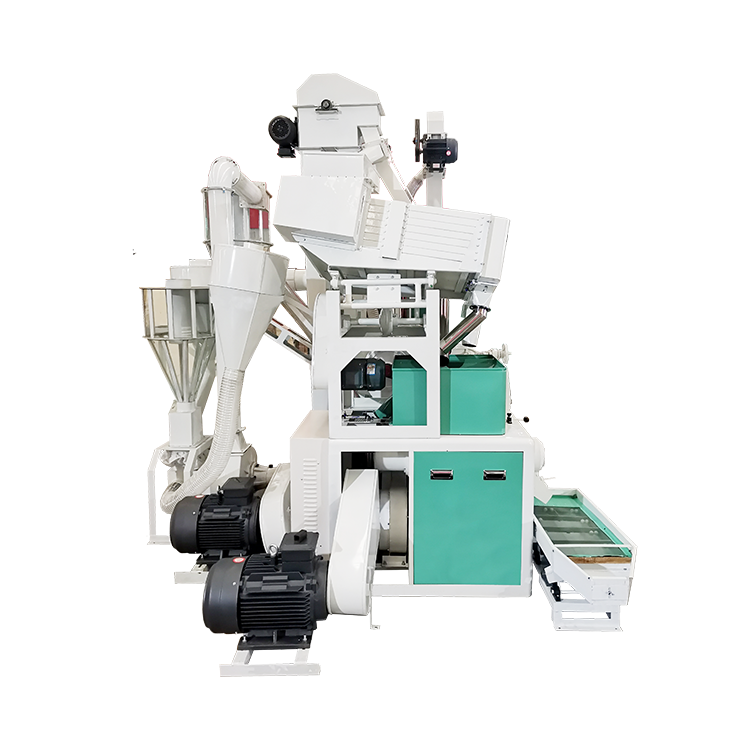

Automatic combined Rice Milling machine

Rice milling machine, highlighting its robust construction, automated capabilities, and efficient performance in removing impurities and hulling rice.

Classification:

Detailed introduction

A rice milling machine, highlighting its robust construction, automated capabilities, and efficient performance in removing impurities and hulling rice.

1. Sturdy and Durable

- Integration with Automobile Manufacturing Technology: The core frame of the machine is built using advanced techniques similar to those used in automobile manufacturing. This ensures that the machine has a strong, resilient core structure that can withstand long-term use without degrading or breaking down.

2. Highly Automated

- Siemens PLC Industrial-Grade System: The machine is equipped with a programmable logic controller (PLC) from Siemens, a leading industrial automation products manufacturer. This system allows for fully automatic operation, including Internet of Things (IoT) integration, which enables remote monitoring and control of the rice milling process.

3. Good Stone Removal Effect

- 3-Level Suspended Vibration Wind Selection: The machine employs a three-stage process of suspended vibration and wind selection to remove stones and other impurities. This multi-step approach ensures a high stone removal rate of over 99%, effectively separating even small impurities like shredded rice.

4. Excellent Hulling Performance

- Rubber Rollers and Rice Hullers: The machine offers both 6-inch and 8-inch rubber rollers, along with manual and pneumatic types of rice hullers. These components are designed with a compact and logical layout, including adaptive pressure adjustment, which leads to effective shelling of the rice with minimal breakage.

5. Advanced Low-Temperature Rice Milling

- Silicon Carbide (Hexagonal) Core Formula: The machine uses silicon carbide grains of 30/24 size as the core formula for cutting the rice skin. This method provides several technical advantages, such as uniform milling without causing breakage, producing white and bright rice, and maintaining a low broken rice rate.

Overall, these features demonstrate that the rice milling machine is designed for efficiency, durability, and quality in the milling process, making it suitable for commercial operations where high throughput and consistent product quality are essential.

| Model | Yield of Rice (Kg) | Milling rate(%) | Net weight of machine (kg) | Capacity (kw) including pulverizer | Power Input (V/hz) | Exterior dimension (mm) | Wooden box packing size (mm) | Gross weight (kg) |

| MLNS 15/15 | 500-700 | 68-75 | 1700 | 32.37 | 380v/50Hz | 3400*2500*2950 | 2300*1450*2280 | 1800 |

| 6LN-20/15S | 800-1100 | 68-75 | 2000 | 40.37 | 380v/50Hz | 3400*2500*2950 | 2300*1450*2280 | 1900 |

If you have any questions about rice mill or rice milling machine, contact our sales team directly!

Previous:

Next:

Language

Language