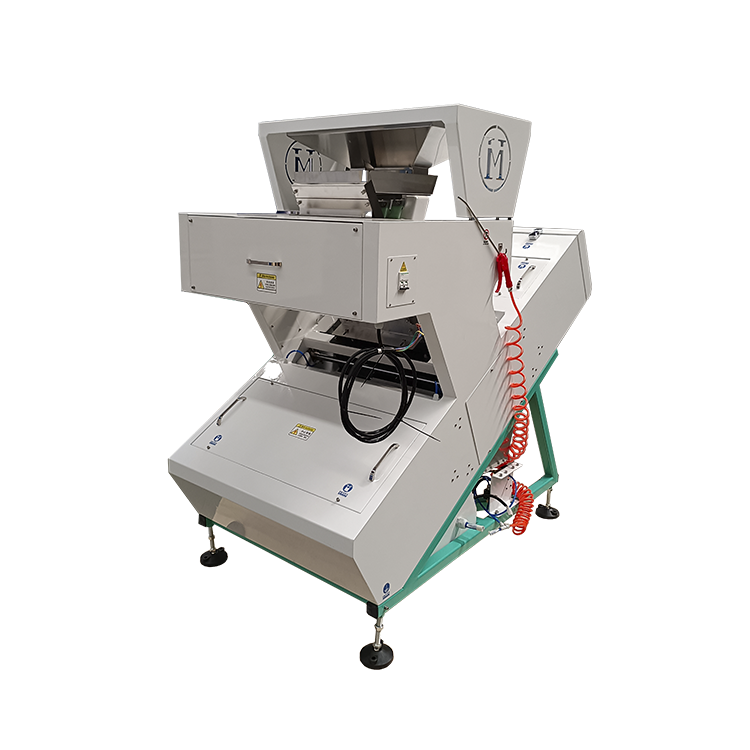

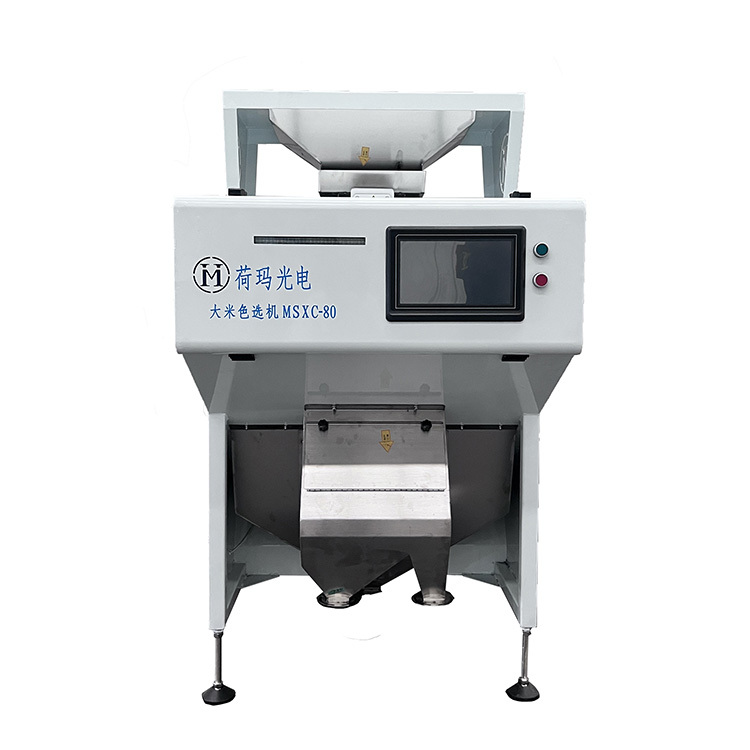

80 rice color sorter

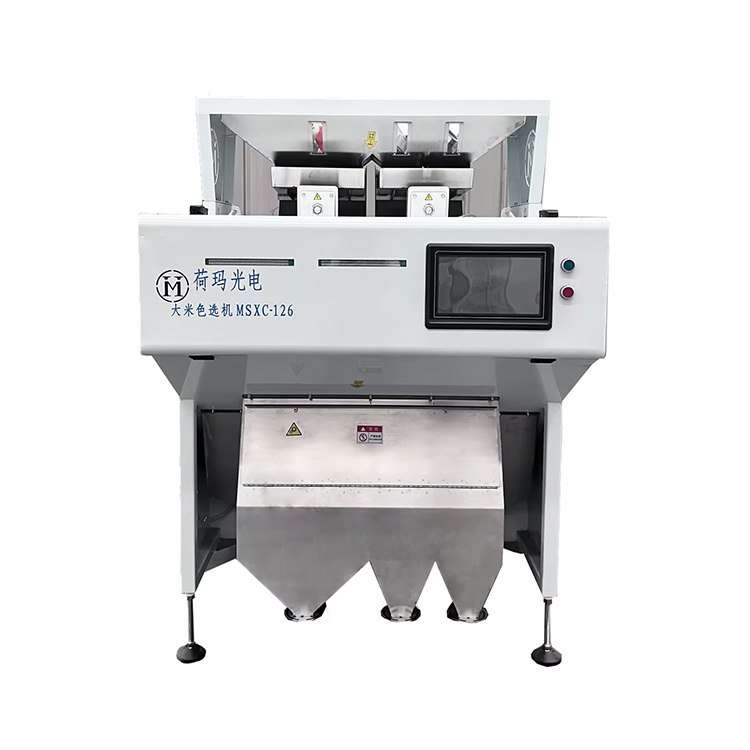

Rice color sorter is a process of screening different color particles and impurities in rice by using CCD optical imaging technology. The rice grains are placed in the chute channel for shaping and speed regulation to form a single layer of uniform speed rice flow that slides out of the chute channel and falls into the CCD lens detection area. The main control system of the color sorter analyzes and judges the meter flow according to the data collected by the CCD lens, and the defective products in the meter flow are blown out by the high-frequency solenoid valve and enter the defective products.

Classification:

Detailed introduction

The rice color sorter operates by utilizing CCD optical imaging technology to screen and separate different colored particles and impurities from the rice. The process begins with rice grains being placed in a chute channel, where they are shaped and regulated to form a single layer of uniformly flowing rice. This rice flow then slides out of the chute channel and falls into the CCD detection area. The color sorter's main control system analyzes the rice flow based on data collected by the CCD camera. Any defective products identified within the rice flow are expelled using a high-frequency solenoid valve and directed into a designated container for defective products.

Main Configuration

Our rice color sorter integrates cutting-edge electronics and biological technologies to significantly enhance material quality. Key components include:

- Feeding Hopper: Ensures a steady supply of rice grains to the sorter.

- Vibrating Feeder: Facilitates the even distribution of rice grains into the chute channel.

- Chute Channel: Guides the rice grains into a single, uniform layer for optimal sorting.

- Light Source and Background Plate: Enhances the contrast for accurate CCD detection.

- CCD Detection System: Capable of identifying and analyzing different colored particles and impurities.

- Discharge Bin: Collects sorted rice grains after the defective products have been removed.

- Air Nozzle: Uses high-frequency solenoid valves to blow out defective products.

- Filter: Maintains a clean operating environment to prevent contamination.

By combining these advanced technologies, our rice color sorter ensures that only the highest quality rice grains pass through to the next stage, providing unparalleled efficiency and precision in material handling.

| Model | Capacity (T/h) | selection accuracy (%) | Take-out ratio (%) | Net weight (kg) | Power (kw) | Power input (V/hz) | Install dimension (mm) | packing size (mm) | Gross weight (kg) |

| MSXC-63/80 | 0.8-1.8 | >99 | <30:1 | 260 | 0.9 | 220v/50Hz | 913*1515*1620 | 1700*1050*1750 | 290 |

| MSXC-126 | 1-3 | >99 | <30:1 | 450 | 1.2 | 220v/50Hz | 1252*1524*1625 | 1800*1150*1850 | 490 |

Key words:

Previous:

Next:

Related recommendations

Consulting Quotation

Sichuan Doujin Technology Co., Ltd, a standard-setting unit of China's fully automatic milling and milling combined rice machine, is a high-tech enterprise integrating R & D, design, production, sales, installation and maintenance.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Language

Language