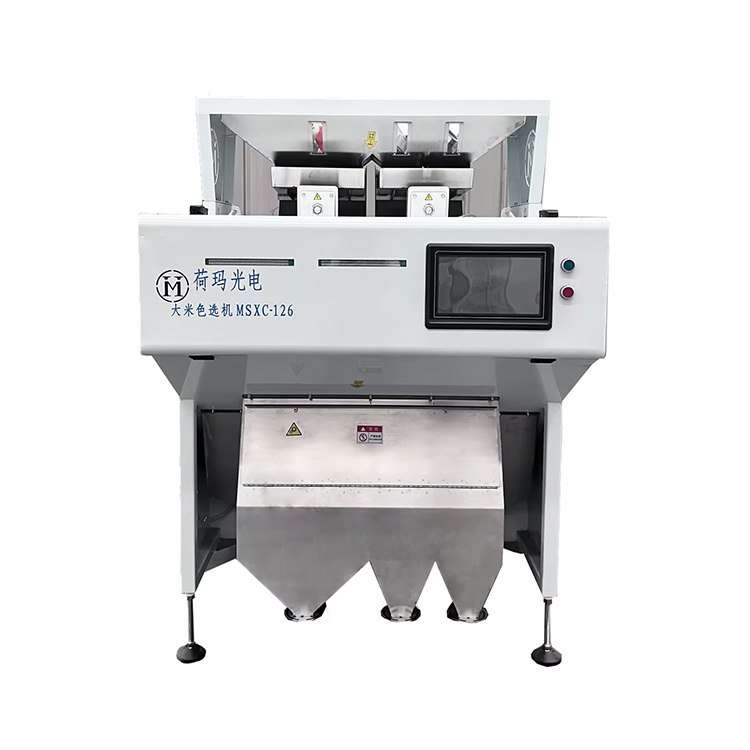

MSXC 126 rice color sorter

Rice color sorter is a process of screening different color particles and impurities in rice by using CCD optical imaging technology. The rice grains are placed in the chute channel for shaping and speed regulation to form a single layer of uniform speed rice flow that slides out of the chute channel and falls into the GGD lens detection area. The main control system of the color sorter analyzes and judges the meter flow according to the data collected by the CCD lens, and the defective products in the meter flow are blown out by the high-frequency solenoid valve and enter the defective products.

Classification:

Detailed introduction

The rice color sorter operates based on CCD optical imaging technology to detect and remove different color particles and impurities from the rice. This process involves several key components and steps:

-

Feeding Hopper: Rice grains are initially placed in the feeding hopper.

-

Vibrating Feeder: From the feeding hopper, the rice moves onto a vibrating feeder, which helps regulate the flow of rice and ensures an even distribution.

-

Chute Channel: The vibrating feeder leads the rice into chute channels designed for shaping and speed regulation. These channels help form a single layer of rice grains moving at a uniform speed.

-

CCD Detection Area: The shaped and regulated rice flow slides out of the chute channel and falls into the CCD detection area. Here, high-resolution line scan cameras capture images of each grain as it passes by.

-

Light Source and Background Plate: A light source illuminates the rice grains, while a background plate provides contrast to enhance the visibility of the grains for the CCD lens.

-

CCD Detection Lens: As the rice flows past the CCD lens, it captures images of each grain. The main control system then analyzes these images to identify any defects or impurities based on color, size, shape, or other characteristics.

-

Discharge Bin: Once the control system identifies defective products, it triggers a high-frequency solenoid valve to blow out the defective grains using precise air jets.

-

Air Nozzle and Air Purifier/Filter: The air nozzle is responsible for removing the defective grains identified by the CCD system. An air purifier and filter system ensure that the air used for this purpose is clean and free of contaminants, which could otherwise compromise the quality of the sorted rice.

-

Main Control System: This system processes the data collected by the CCD and makes real-time decisions on which grains need to be ejected. It also manages the overall operation of the sorter to ensure accuracy and efficiency.

Main Configuration Benefits

The integration of electronics and biology in the rice color sorter's design allows for significant improvements in material quality. By accurately identifying and removing discolored, underdeveloped, or otherwise defective grains, the sorter ensures that only high-quality rice proceeds to the next stages of processing or packaging. This not only enhances the final product's marketability but also can increase consumer satisfaction and trust in the brand.

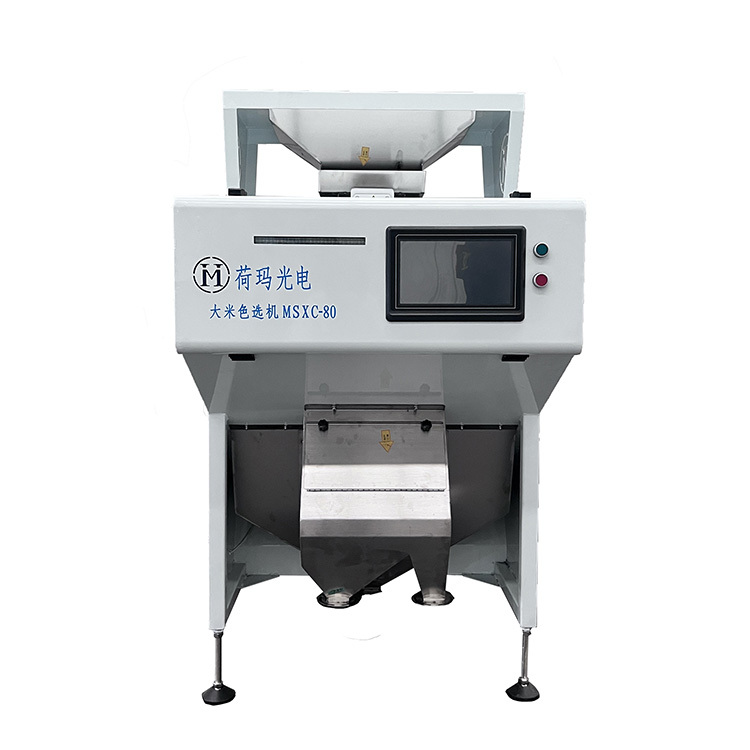

| Model | Capacity (T/h) | accuracy (%) | Take-out ratio (%) | Net weight (kg) | Power (kw) | Power input (V/hz) | Exterior dimension (mm) | Wooden box packing size (mm) | Gross weight (kg) |

| MSXC-63/80 | 0.8-1.8 | >99 | <30:1 | 260 | 0.9 | 220v/50Hz | 913*1515*1620 | 1700*1050*1750 | 290 |

| MSXC-126 | 1-3 | >99 | <30:1 | 450 | 1.2 | 220v/50Hz | 1252*1524*1625 | 1800*1150*1850 | 490 |

Key words:

color sorter, rice color sorter, color sortex

Previous:

Related recommendations

Consulting Quotation

Sichuan Doujin Technology Co., Ltd, a standard-setting unit of China's fully automatic milling and milling combined rice machine, is a high-tech enterprise integrating R & D, design, production, sales, installation and maintenance.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Language

Language