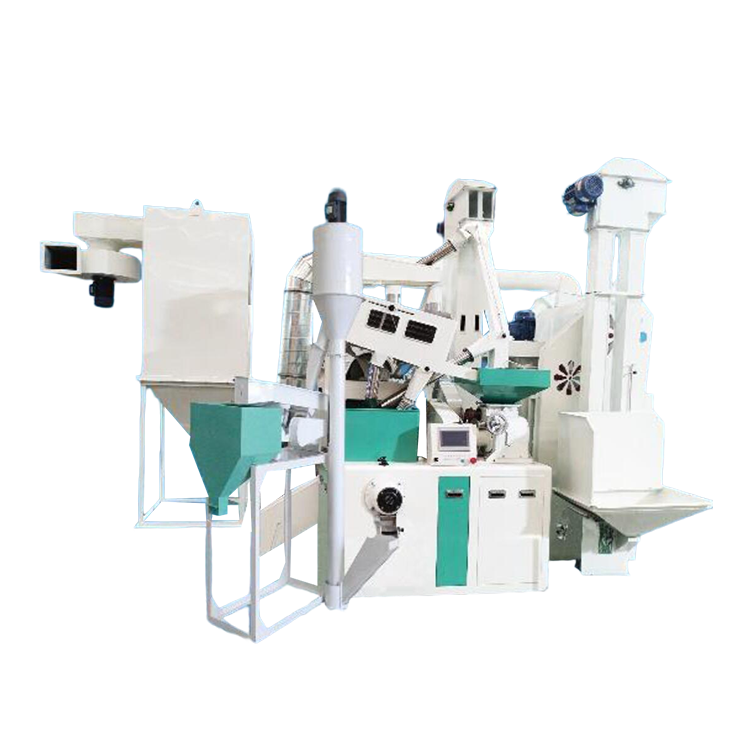

Automatic rice milling machine

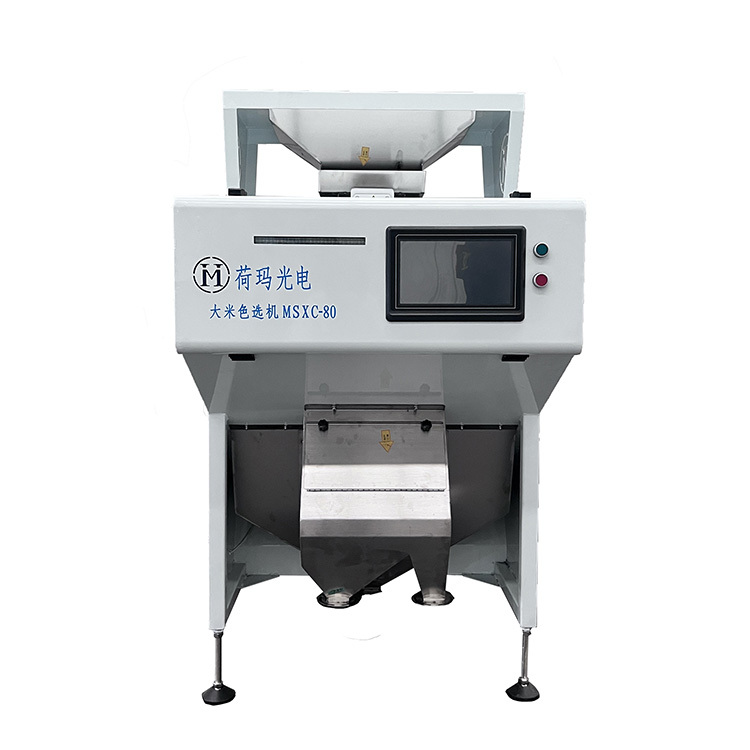

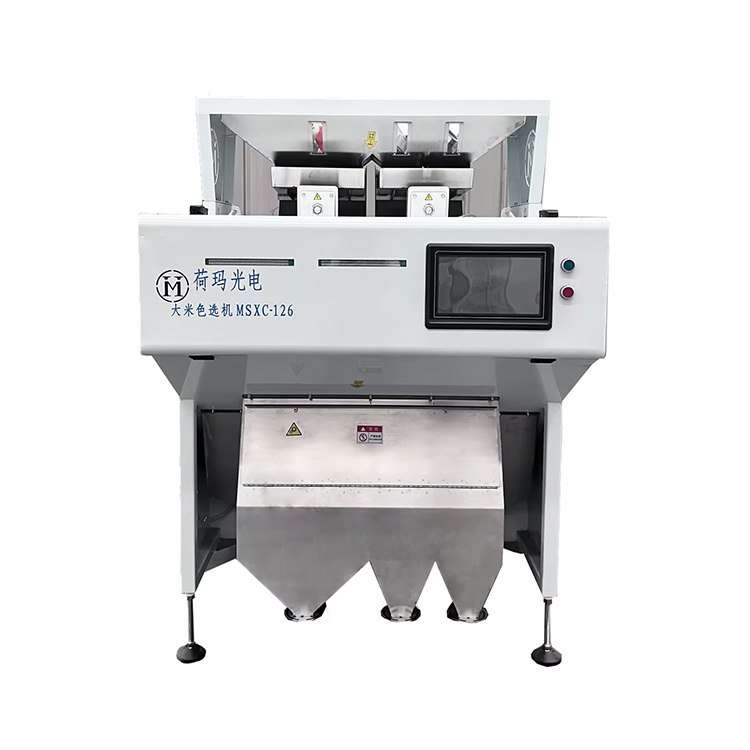

Holmer developed innovative automatic unmanned control combination of rice milling machine, rice polishing machine, rice color sorting machine and other advanced complete sets of equipment

Classification:

Detailed introduction

Description

1. Sturdy and Durable Construction

- Core Frame: Our rice milling machine features a core frame that is integrated with advanced automobile manufacturing technology. This ensures that the core skeleton of the entire machine is robust and indestructible, offering longevity and durability in demanding operational environments.

2. High Automation for Efficiency

- Siemens PLC System: Equipped with a Siemens PLC industrial-grade system, our machine realizes fully automatic Internet of Things (IoT) rice milling functions. This high level of automation enhances efficiency, reduces manual intervention, and ensures consistent performance.

3. Effective Stone Removal

- Three-Level Suspended Vibration Wind Selection: The machine employs a three-level suspended vibration wind selection process to meticulously remove impurities. With a stone removal rate exceeding 99%, it effectively separates shredded rice and other impurities, ensuring high-quality output.

4. Superior Hulling Performance

- Rubber Rollers: Available in both 6' and 8' options, our rubber rollers provide exceptional hulling performance. We offer both manual and pneumatic rice hullers, featuring compact and reasonable layouts that adapt to varying pressure needs. This results in high shelling efficiency and minimal breakage.

5. Advanced Low-Temperature Rice Milling

- Core Formula: Utilizing silicon carbide (hexahedral) with a particle size of 30/24, our machine achieves superior rice milling performance. This advanced formula ensures uniform milling, prevents breakage, and produces white and bright rice with a low broken rice rate. The low-temperature milling technique further enhances the quality and integrity of the rice grains.

| Model | Yield of Rice (kg) | Milling rate (%) | Net weight (kg) | Power (kw) including crusher | Power Input (V/hz) | install dimension (mm) | Wooden packing size (mm) | Gross weight (kg) |

| MLNS 15/15 | 500-700 | 68-75 | 1700 | 32.37 | 380v/50Hz | 3400*2500*2950 | 2300*1450*2280 | 1800 |

| 6LN-20/15S | 800-1100 | 68-75 | 2000 | 40.37 | 380v/50Hz | 3400*2500*2950 | 2300*1450*2280 | 1900 |

Holmer developed innovative automatic unmanned control combination of rice milling machine, rice polishing machine, rice color sorting machine and other advanced complete sets of equipment

Key words:

rice mill, rice milling machine, automatic rice mill, automatic rice milling machine, rice mill for sale, rice milling machine for sale, rice mill manufacturer, rice mill factory, rice mill machine factory, 1 ton per hour rice milling machine

Related recommendations

Consulting Quotation

Sichuan Doujin Technology Co., Ltd, a standard-setting unit of China's fully automatic milling and milling combined rice machine, is a high-tech enterprise integrating R & D, design, production, sales, installation and maintenance.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Language

Language