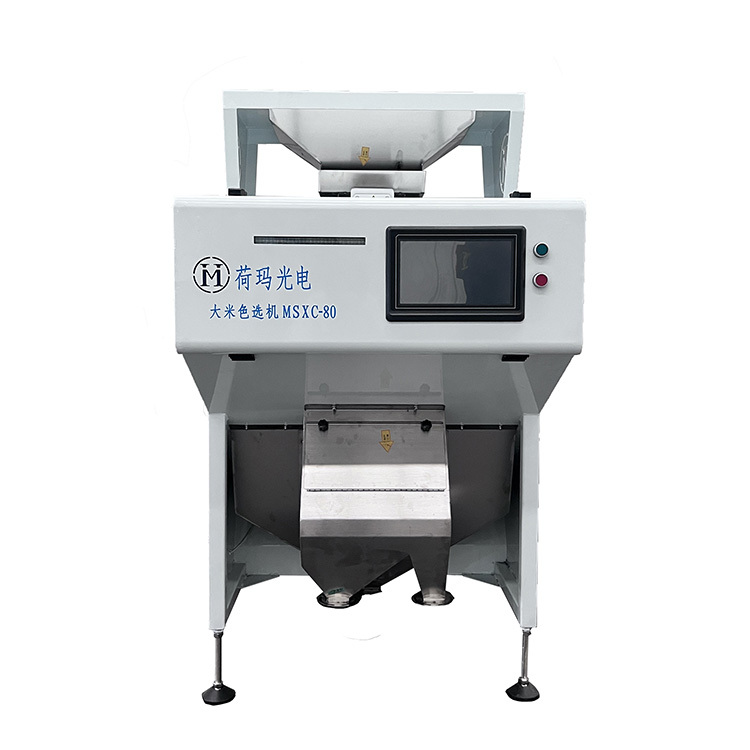

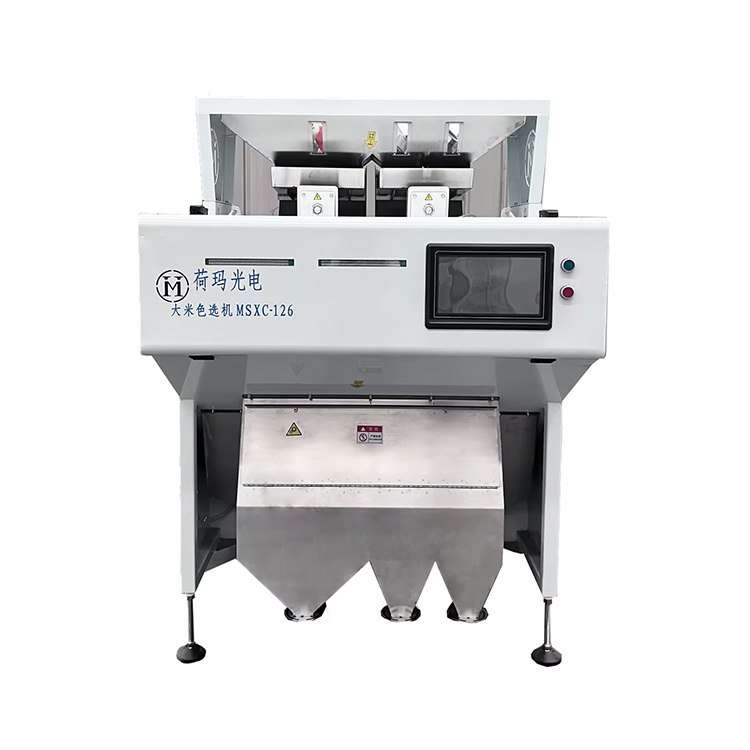

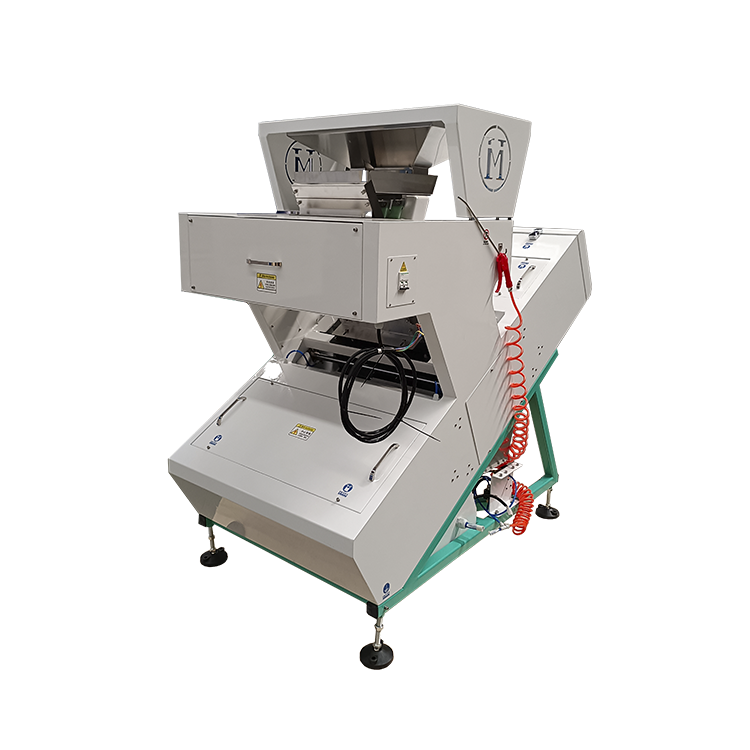

Rice color sorter is a process of screening different color particles and impurities in rice by using CCD optical imaging technology. The rice grains are placed in the chute channel for shaping and speed regulation to form a single layer of uniform speed rice flow that slides out of the chute channel and falls into the GGD lens detection area. The main control system of the color sorter analyzes and judges the meter flow according to the data collected by the CCD lens, and the defective products in the meter flow are blown out by the high-frequency solenoid valve and enter the defective products.

Operation video

Maintenance video

Rice color sorter is a process of screening different color particles and impurities in rice by using CCD optical imaging technology. The rice grains are placed in the chute channel for shaping and speed regulation to form a single layer of uniform speed rice flow that slides out of the chute channel and falls into the GGD lens detection area. The main control system of the color sorter analyzes and judges the meter flow according to the data collected by the CCD lens, and the defective products in the meter flow are blown out by the high-frequency solenoid valve and enter the defective products.

Operation video

Maintenance video

Rice color sorter is a process of screening different color particles and impurities in rice by using CCD optical imaging technology. The rice grains are placed in the chute channel for shaping and speed regulation to form a single layer of uniform speed rice flow that slides out of the chute channel and falls into the GGD lens detection area. The main control system of the color sorter analyzes and judges the meter flow according to the data collected by the CCD lens, and the defective products in the meter flow are blown out by the high-frequency solenoid valve and enter the defective products.

Operation video

Maintenance video

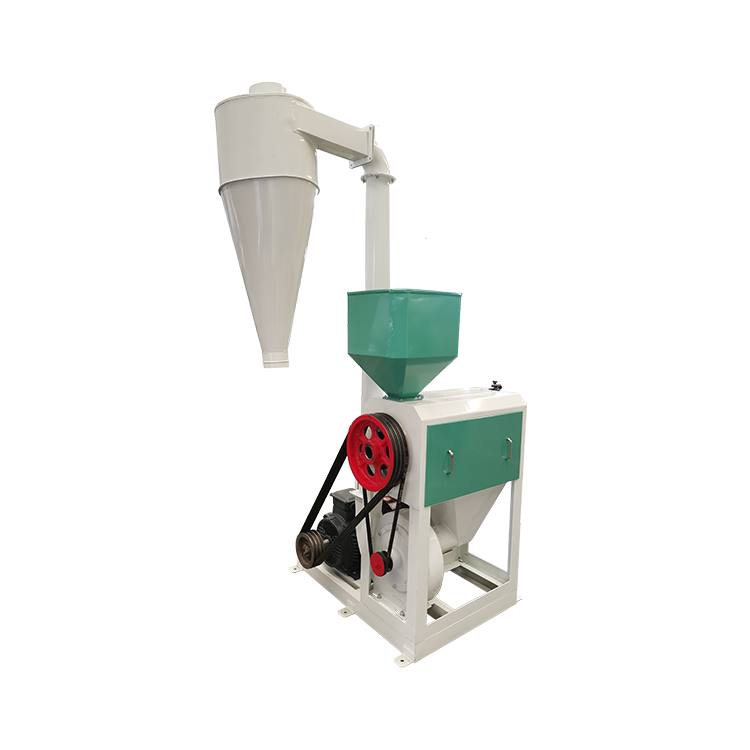

Rice water mist polishing machine

White rice enters the polishing chamber of the polishing machine, and under specific pressure and infiltration of water mist, the surface of the rice grains is polished by friction, thus forming a 50-20 micron thick gelatinized layer on the surface, which can not only remove the floating bran on the surface of the rice grains, but also make the starch on the surface of the rice grains paste to make up for cracks, so that the rice can obtain glittering and bright appearance quality. Increase taste and chewiness, improve the storage performance and commodity value of rice.

Operation video

Maintenance video

Rice color sorter is a process of screening different color particles and impurities in rice by using CCD optical imaging technology. The rice grains are placed in the chute channel for shaping and speed regulation to form a single layer of uniform speed rice flow that slides out of the chute channel and falls into the CCD lens detection area. The main control system of the color sorter analyzes and judges the meter flow according to the data collected by the CCD lens, and the defective products in the meter flow are blown out by the high-frequency solenoid valve and enter the defective products.

Operation video

Maintenance video

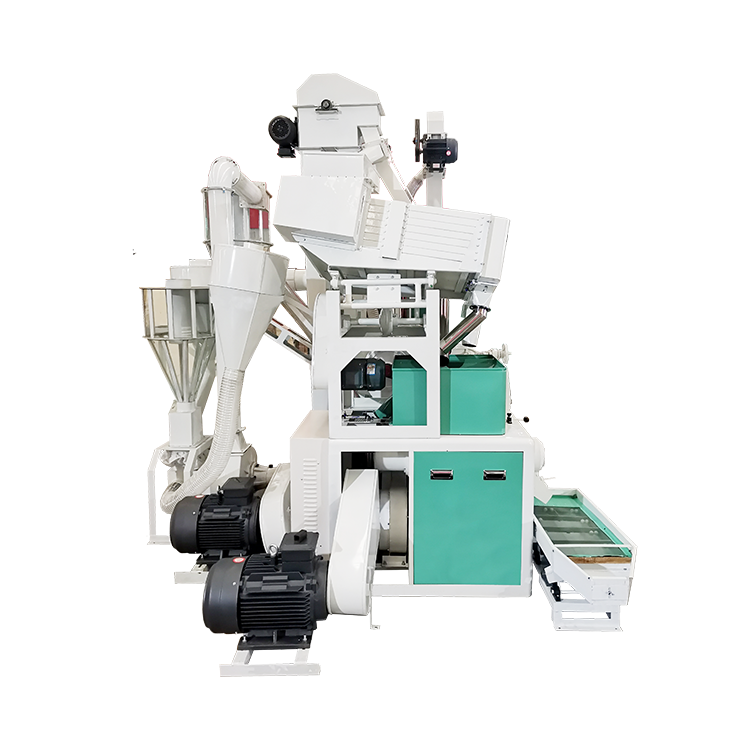

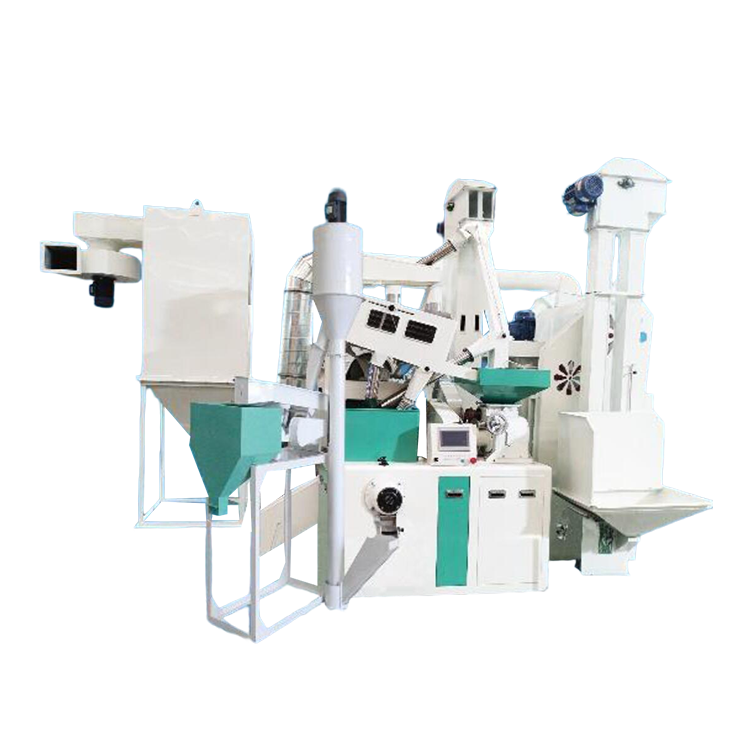

Automatic combined Rice Milling machine

Rice milling machine, highlighting its robust construction, automated capabilities, and efficient performance in removing impurities and hulling rice.

Operation video

Maintenance video

Automatic rice milling machine

Holmer developed innovative automatic unmanned control combination of rice milling machine, rice polishing machine, rice color sorting machine and other advanced complete sets of equipment

Operation video

Maintenance video

The Homa grain Machinery cleaning and stone removal machine adopts a circular bucket for initial cleaning and automatic removal of large impurities without the need for manual grasping. It exclusively uses a mixed specific gravity stone removal rate of over 99.99%.

Operation video

Maintenance video

Deluxe Edition - Six-sided Vacuum Packaging Machine

AMparameterscanbeautomaticallycorrected,usinghigh-end intelienttouchscreencentralizedcontrol ofreal-time trackingsystemstatus.The equipmenthasautomaticetection functiontodetect faults anddisplayfaut information inreal time.Theuse ofwell-knownbrandcomponents,itsworktandrleeiceeoeedosntoolepichingfkaginsizshrmission reserved RS485/232 serial interface, can communicate with the central control system.

Operation video

Maintenance video

Standard Version - Double-sided Vacuum Packaging Machine

AMparameterscanbeautomaticallycorrected,usinghigh-end intelienttouchscreencentralizedcontrol ofreal-time trackingsystemstatus.The equipmenthasautomaticetection functiontodetect faults anddisplayfaut information inreal time.Theuse ofwell-knownbrandcomponents,itsworktandrleeiceeoeedosntoolepichingfkaginsizshrmission reserved RS485/232 serial interface, can communicate with the central control system.

Operation video

Maintenance video

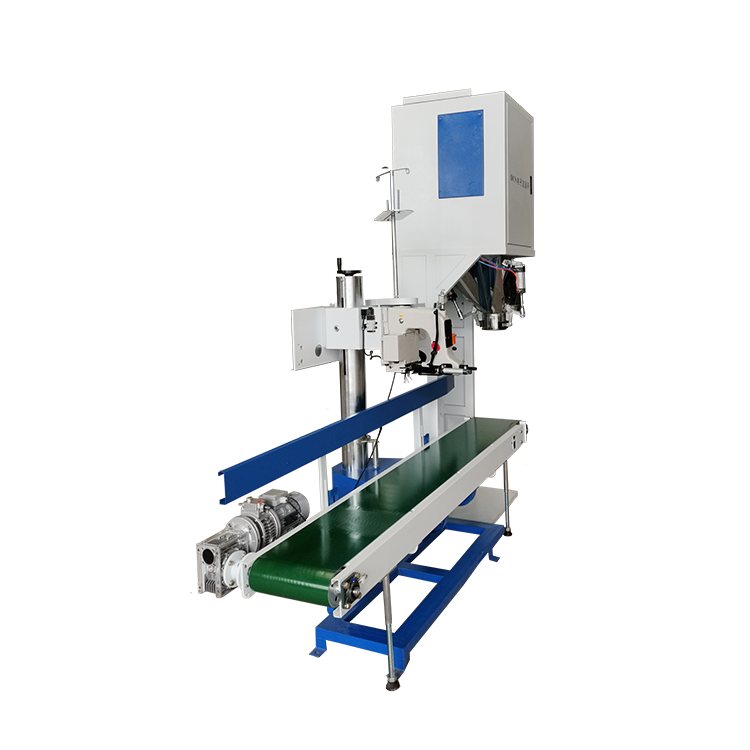

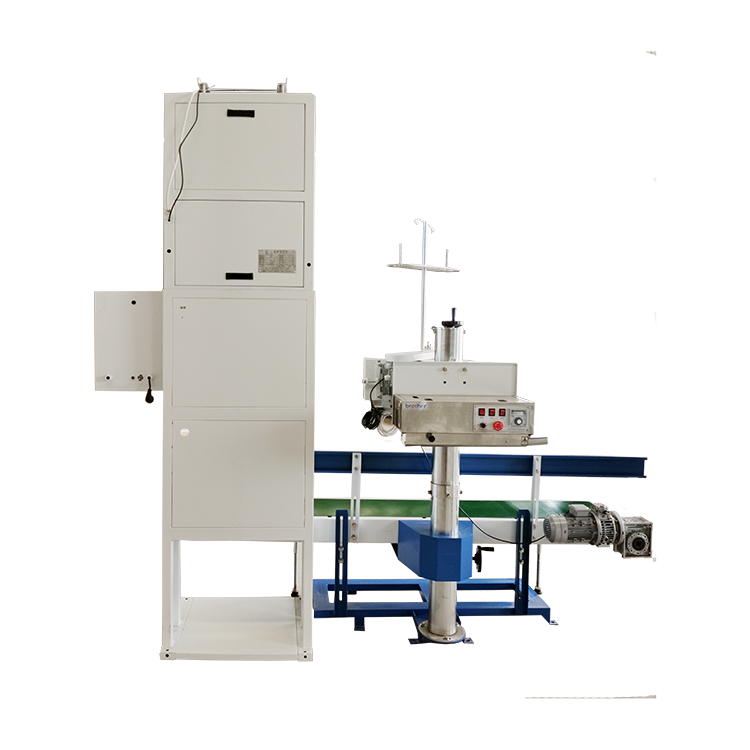

Electronic quantitative packing machine

The new double display instrument has high measurement accuracy, stable performance, can display the cumulative weight, the number of packages, and the operation is more simple and quick.

Operation video

Maintenance video

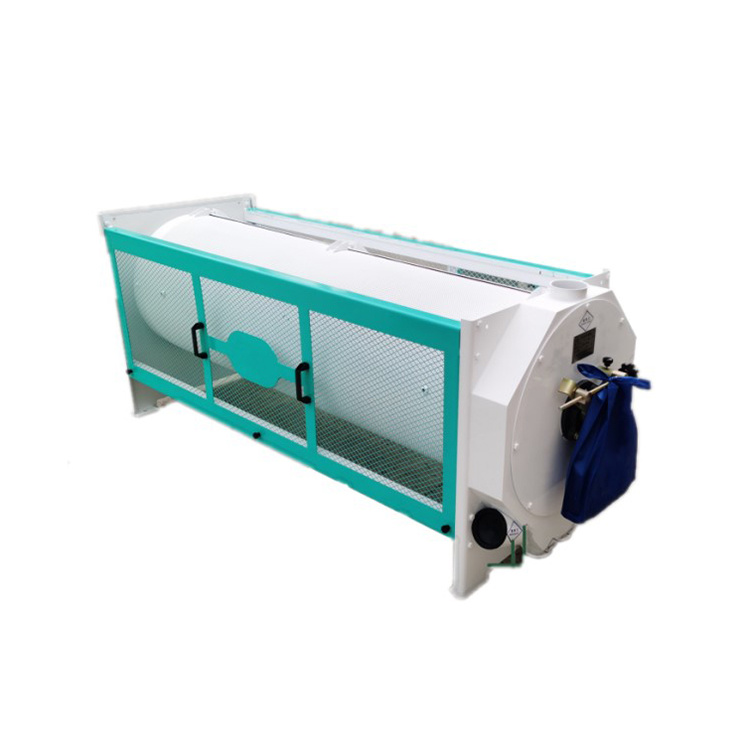

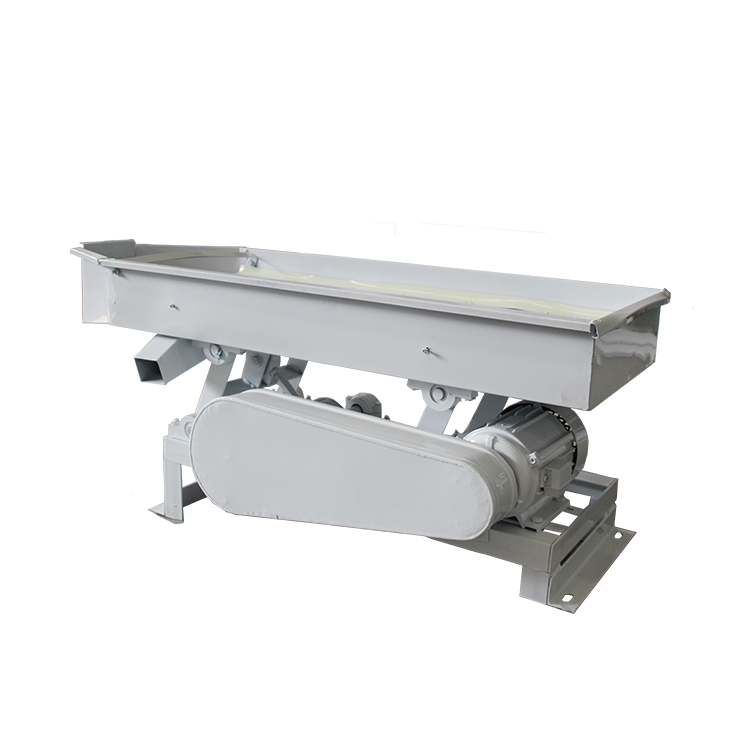

Gravity Separator for rice mill

The Gravity Separator uses the physical characteristics of the specific gravity, particle size, friction coefficient and other aspects of the rice and brown rice. Under the action of the horizontal reciprocating shaking separation plate, the grain roughness mixture gradually produces automatic classification, so that the brown rice with large specific gravity and small particle size sinks, and the two-way inclined convex point separation plate transports, so that the brown rice moves obliquely upward and flows out above the separation plate; the small specific gravity, large grain size rice is floating in the upper layer of brown rice. Slope down to the outlet below the separation, so as to achieve the result of qualitative separation.

Operation video

Maintenance video

The husker controls the gap of the rubber rollers by adjusting the position, and uses a special winding method to realize the line speed difference between the positive and negative rotation of the two rubber rollers to carry out the husking of rice. The core part is the adjustable bearing sleeve, which is easier to maintain than the old gear wheel structure and achieves better peeling effect.

Operation video

Maintenance video

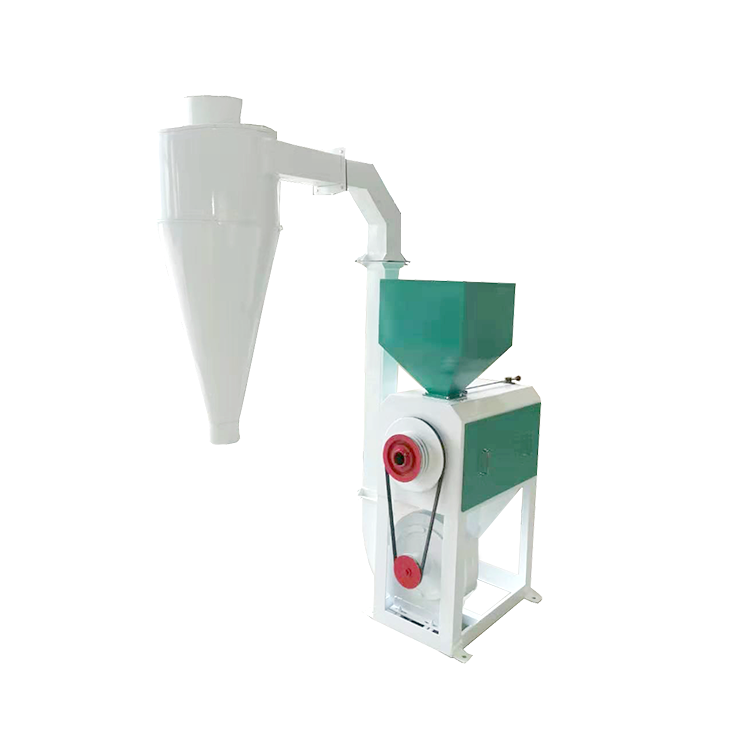

Emery Roller Rice Whitener Machine

The lengthened sand roller has a large grinding area and good white grinding effect. Strong wind rice milling machine can be equipped with iron polishing head and polyurethane polishing head, and various rice milling machine schemes can be flexibly selected. Simple operation and convenient maintenance.

Operation video

Maintenance video

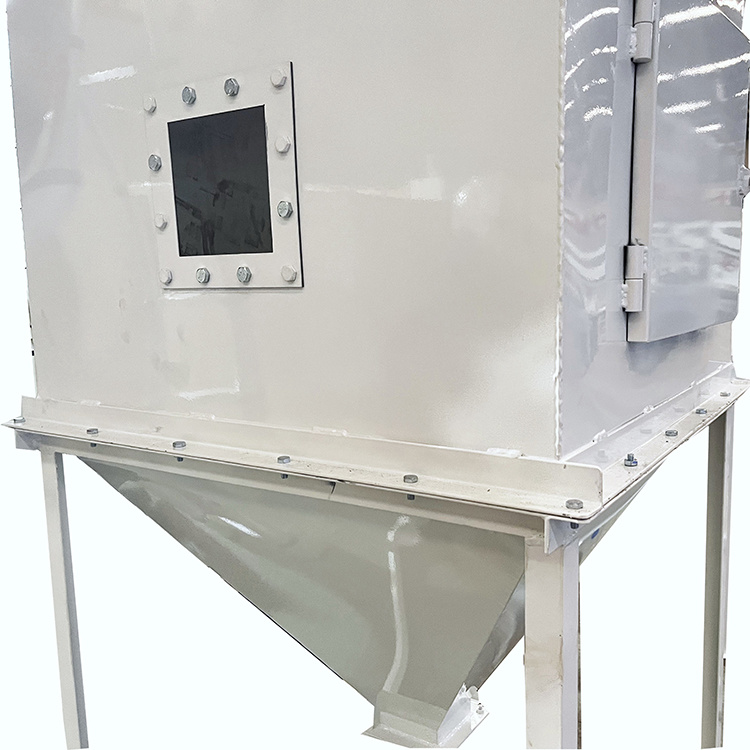

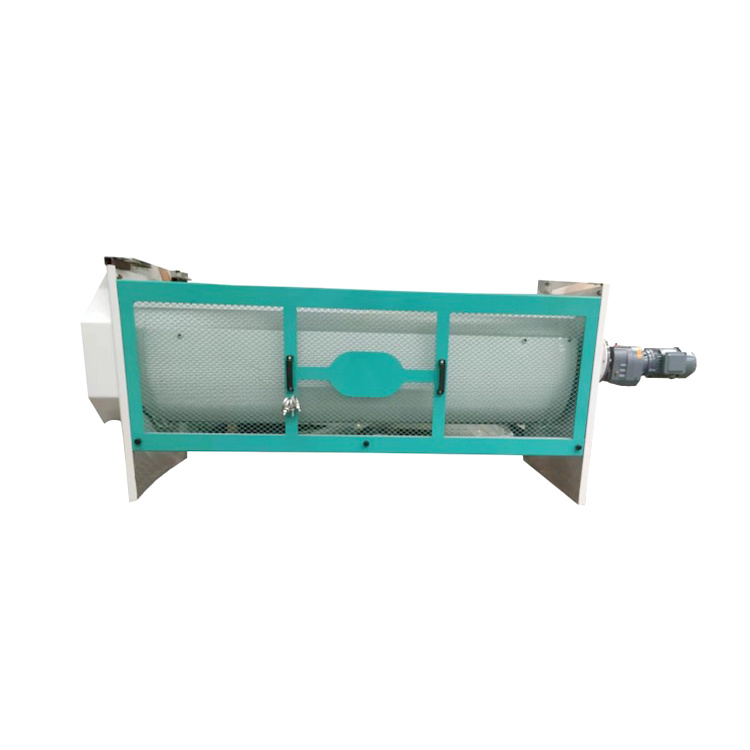

Pulse dust collector is a commonly used industrial dust removal equipment, which is mainly used to treat particulate matter in industrial waste gas.

Operation video

Maintenance video

The motor-driven screen cylinder rotation is a selection equipment for separating complete rice and broken rice from rice grains, and can remove round stones and barnyard seeds with the same width as rice grains. Used in the last process of the rice factory, can also be used for other grain classification, so that the finished rice more commercial value.

Operation video

Maintenance video

The use of broken rice and whole rice grain type difference, in the plane of the screen surface for overlapping rotation, friction propulsion to form automatic classification screening.

Operation video

Maintenance video

Language

Language