Gravity Separator for rice mill

The Gravity Separator uses the physical characteristics of the specific gravity, particle size, friction coefficient and other aspects of the rice and brown rice. Under the action of the horizontal reciprocating shaking separation plate, the grain roughness mixture gradually produces automatic classification, so that the brown rice with large specific gravity and small particle size sinks, and the two-way inclined convex point separation plate transports, so that the brown rice moves obliquely upward and flows out above the separation plate; the small specific gravity, large grain size rice is floating in the upper layer of brown rice. Slope down to the outlet below the separation, so as to achieve the result of qualitative separation.

Classification:

Detailed introduction

Working Principle

The Gravity Separator is a critical component in rice processing lines, utilizing the physical characteristics of specific gravity, particle size, and friction coefficient to differentiate between rice and brown rice. The process involves a horizontal reciprocating shaking separation plate that gradually sorts the grain roughness mixture automatically. Brown rice, having a larger specific gravity and smaller particle size, sinks and is transported by the two-way inclined convex point separation plate, causing it to move obliquely upward and flow out above the separation plate. Conversely, rice with a smaller specific gravity and larger grain size floats on the upper layer and slopes down to the outlet below the separation plate, thus achieving qualitative separation.

Functional Features

- Smooth Operation: Ensures balanced and stable performance throughout the sorting process.

- Low Energy Consumption: Designed for efficiency, reducing operational costs.

- Low Noise: Operates quietly, making it suitable for various environments.

- High Yield: Maximizes the output of high-quality separated products.

- Sturdy and Durable Equipment: Built to withstand rigorous use over long periods.

- Fast Maintenance: Designed for quick and easy maintenance to minimize downtime.

By integrating these features, the Gravity Separator ensures effective and efficient separation, enhancing the overall quality and productivity of rice processing operations.

| Model | Capacity (T/H) | Net weight (kg) | power (kw) | Power input (V/hz) | Install dimension (mm) | packing size (mm) | Gross weight (kg) |

| MGCS 80-5 | 0.5-0.7 | 200 | 0.75 | 380v/50Hz | 1100*800*1100 | 1200*900*1300 | 230 |

| MGCS 80-7 | 0.8-1.1 | 220 | 0.75 | 380v/50Hz | 1100*800*1100 | 1200*900*1400 | 250 |

Key words:

separator, brown rice separator, gravity separator, rice mill, rice milling machine, factory, manufacturer, made in china

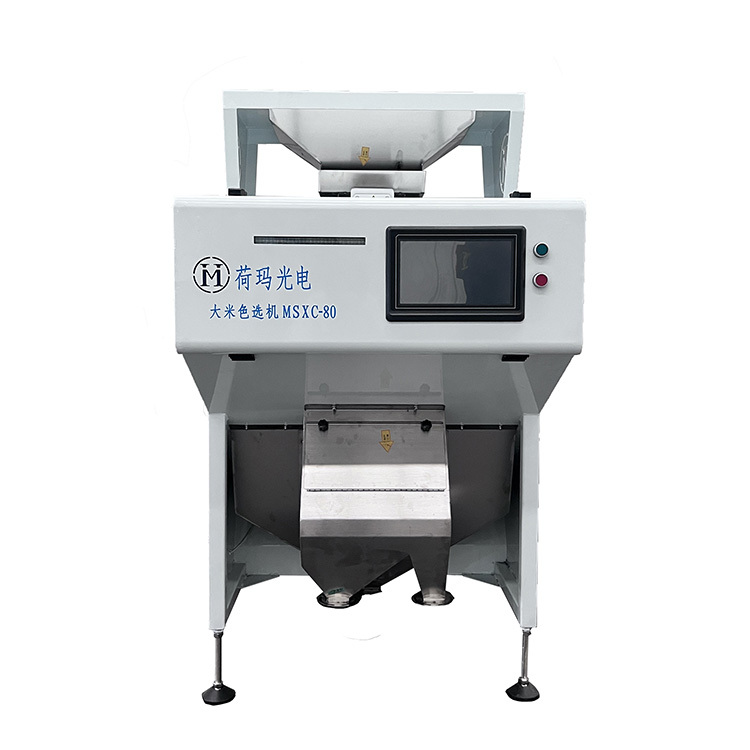

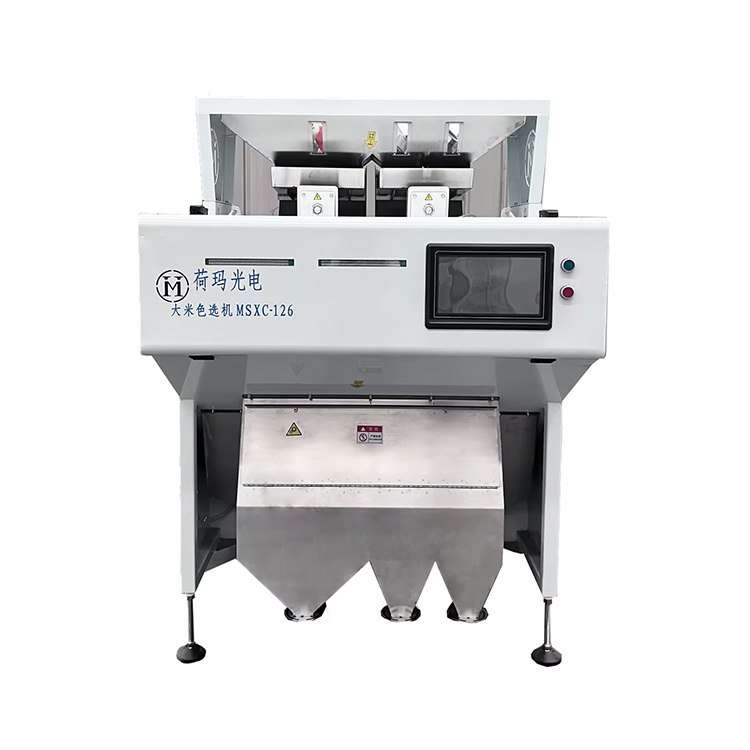

Related recommendations

Consulting Quotation

Sichuan Doujin Technology Co., Ltd, a standard-setting unit of China's fully automatic milling and milling combined rice machine, is a high-tech enterprise integrating R & D, design, production, sales, installation and maintenance.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Language

Language