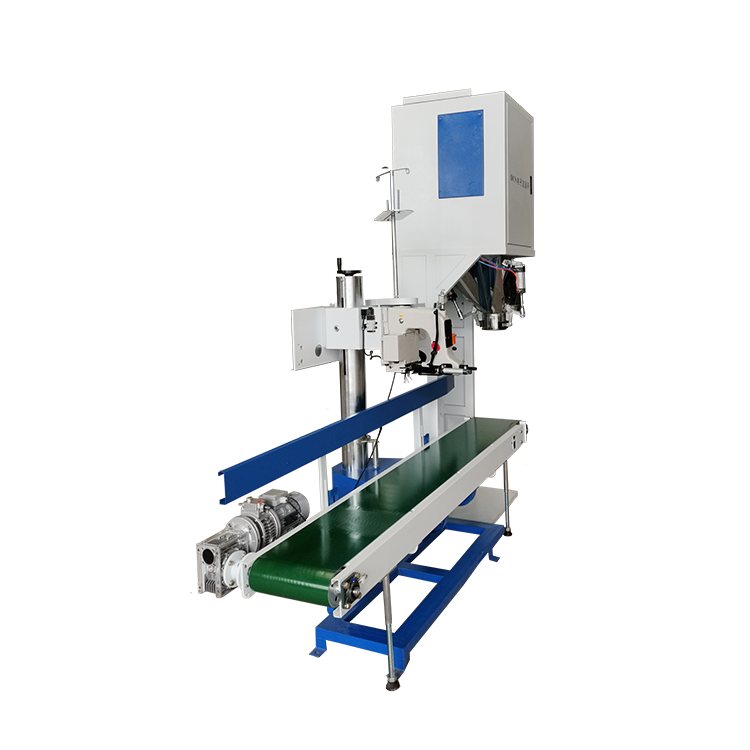

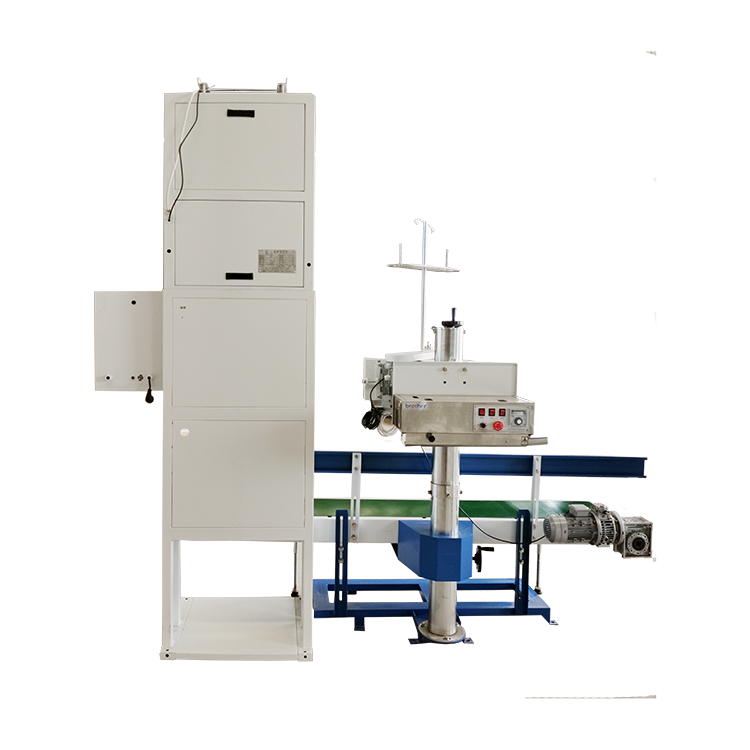

Electronic quantitative packing machine

The new double display instrument has high measurement accuracy, stable performance, can display the cumulative weight, the number of packages, and the operation is more simple and quick.

Classification:

Detailed introduction

• Functional features

The new double display instrument has high measurement accuracy, stable performance, can display the cumulative weight, the number of packages, and the operation is more simple and quick.

Adaptive software, with automatic setting of control parameters, fall correction, out-of-tolerance alarm, fault self-diagnosis and other functions.

Wide quantitative range, high precision, with the table can be lifted conveying sewing machine, a machine for multiple purposes, high efficiency.

Imported sensors are used. Pneumatic actuator, reliable work, simple maintenance, no pollution.

The casing adopts advanced powder coated tech., and the material contact parts are made of imported stainless steel materials, which have high sanitary standards, corrosion resistance and long service life .

| Model | Range (kg) | Net weight (kg) | Overall power (kw) | Power supply (V/hz)(MPa) | Actuators | Accuracy | Install dimension (mm) | packing size (mm) | Gross weight (kg) |

| HM-50A | 5-50 | 400 | 1 |

AC220V 50HZ 0.4-0.8MPa |

Pneumatic | ×(0.2)×(0.1) | 2560*650*715 |

1100*740*1800 2200*760*760 |

500 |

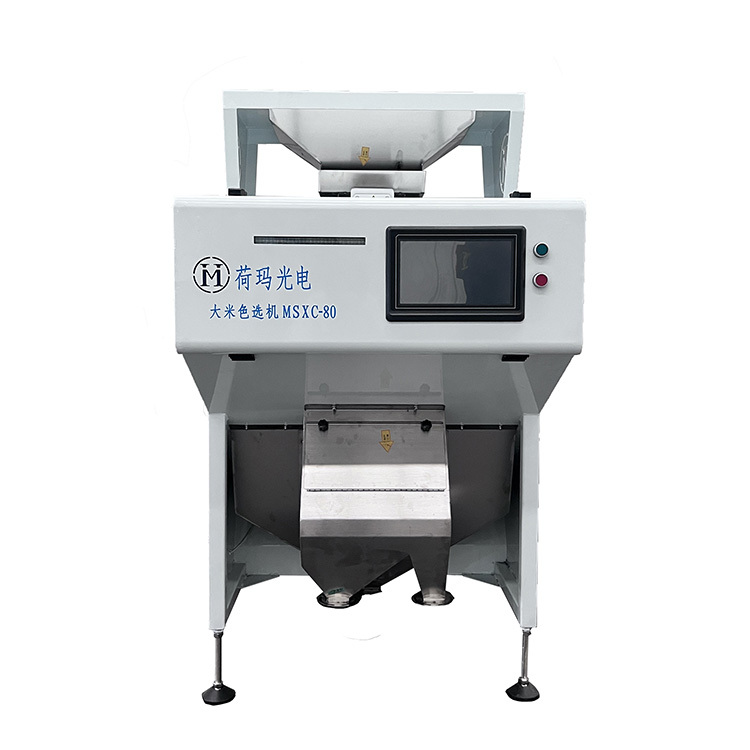

Key words:

packing machine, rice mill, rice processing plant, rice processing

Related recommendations

Consulting Quotation

Sichuan Doujin Technology Co., Ltd, a standard-setting unit of China's fully automatic milling and milling combined rice machine, is a high-tech enterprise integrating R & D, design, production, sales, installation and maintenance.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Language

Language