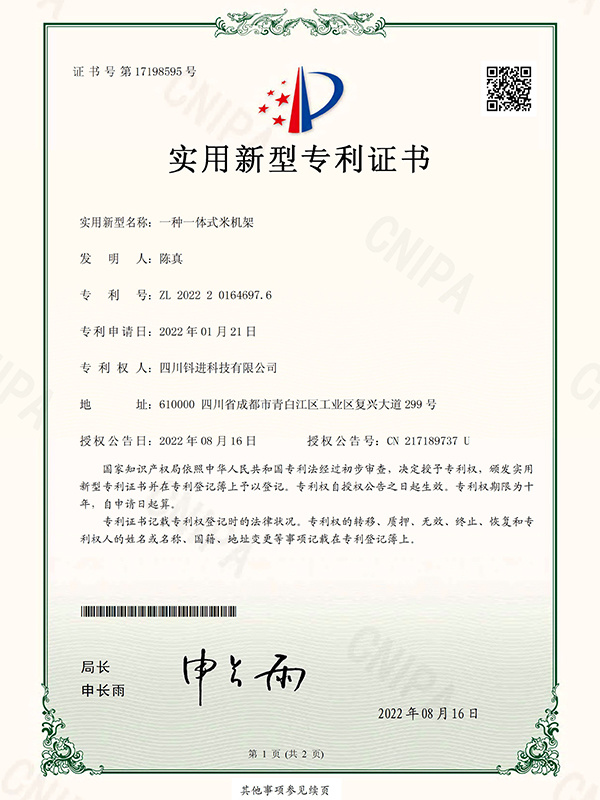

Patent for color sorter

Main features and technical advantages of Novel Color Sorter: Advanced optical recognition technology: New color sorters usually use high-resolution CCD or CMOS cameras to detect the color and morphology of rice grains through precise optical sensors and image recognition algorithms. This enables the color sorter to quickly and accurately identify and sort rice grains of different colors or defects. Efficient sorting: The color sorter scans the material flow through a high-speed camera and quickly separates unqualified rice grains from qualified rice through air jet technology. Its sorting speed can reach hundreds of kilograms per minute, greatly improving production efficiency. Intelligent control system: New color sorters are usually equipped with intelligent control systems that can adjust sorting parameters (such as color, size, shape, brightness, etc.) in real time to adapt to the characteristics of different batches of rice and ensure the optimization of sorting effects. High-precision sorting: Through intelligent algorithms, new color sorters can accurately identify and process rice grains of different colors and defects. It can distinguish even minor color changes and damages, ensuring higher purity and more stable quality of sorted rice. Energy saving and environmental protection: New color sorters usually adopt efficient energy management technology to reduce energy consumption and production costs. At the same time, the design of the equipment also takes environmental factors into consideration to reduce exhaust emissions and noise pollution. Strong adaptability: New color sorters can handle different types of rice, including long-grain rice, short-grain rice, glutinous rice, fragrant rice, etc., and can also adapt to the sorting needs of different impurity types (such as stones, weeds, broken rice, black rice, etc.).

Classification:

Detailed introduction

Main features and technical advantages of Novel Color Sorter:

Advanced optical recognition technology:

New color sorters usually use high-resolution CCD or CMOS cameras to detect the color and morphology of rice grains through precise optical sensors and image recognition algorithms. This enables the color sorter to quickly and accurately identify and sort rice grains of different colors or defects.

Efficient sorting:

The color sorter scans the material flow through a high-speed camera and quickly separates unqualified rice grains from qualified rice through air jet technology. Its sorting speed can reach hundreds of kilograms per minute, greatly improving production efficiency.

Intelligent control system:

New color sorters are usually equipped with intelligent control systems that can adjust sorting parameters (such as color, size, shape, brightness, etc.) in real time to adapt to the characteristics of different batches of rice and ensure the optimization of sorting effects.

High-precision sorting:

Through intelligent algorithms, new color sorters can accurately identify and process rice grains of different colors and defects. It can distinguish even minor color changes and damages, ensuring higher purity and more stable quality of sorted rice.

Energy saving and environmental protection:

New color sorters usually adopt efficient energy management technology to reduce energy consumption and production costs. At the same time, the design of the equipment also takes environmental factors into consideration to reduce exhaust emissions and noise pollution.

Strong adaptability:

New color sorters can handle different types of rice, including long-grain rice, short-grain rice, glutinous rice, fragrant rice, etc., and can also adapt to the sorting needs of different impurity types (such as stones, weeds, broken rice, black rice, etc.).

Language

Language