De-stoner of Holmer rice milling machine

When the machine is working, the raw grain is naturally fed from the inlet of the circular sieve. As the circular sieve runs at low speed and matches the corresponding circular sieve pieces, the rice enters the field sieve from the sieve holes to remove circular sundries twice, and finally enters the fish scale sieve to the sorting chamber of the specific gravity stone remover. The sundries with a volume larger than the rice are automatically discharged from the miscellaneous outlet. Under the action of specific frequency vibration and mixed airflow, the grains with small specific gravity density are suspended in the upper layer, and the stones with large specific gravity density sink into the bottom layer, contact with the fish scale sieve surface, and the shape separation is automatically discharged from the stone removal port.

Operation video

Maintenance video

Bran Crusher for rice milling machine

Through the rotation of the main shaft, the hammer piece is driven to run at high speed, so that the rice husk is crushed by the impact of the tooth plate, friction and collision between the materials, and the size of the sieve hole affects the thickness of the rice bran.

Operation video

Maintenance video

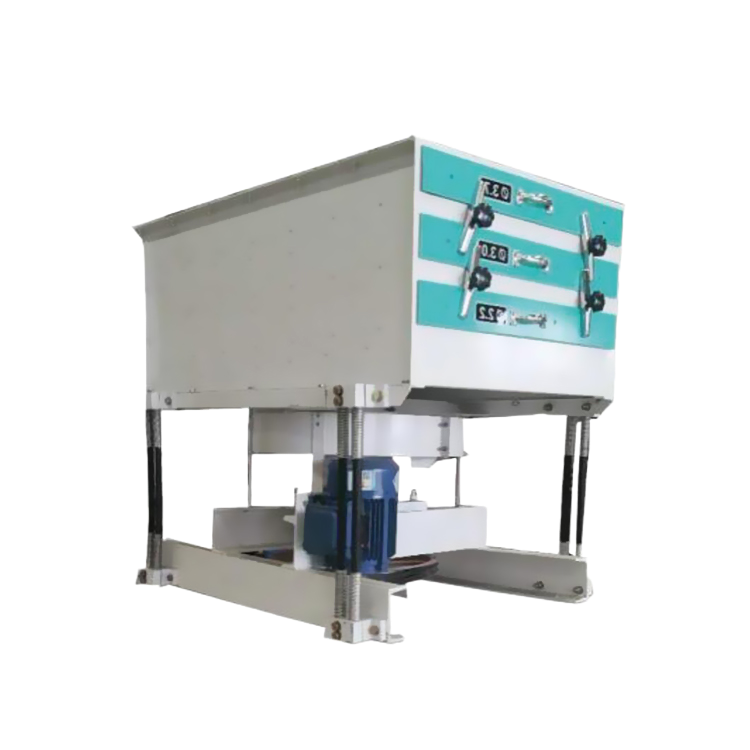

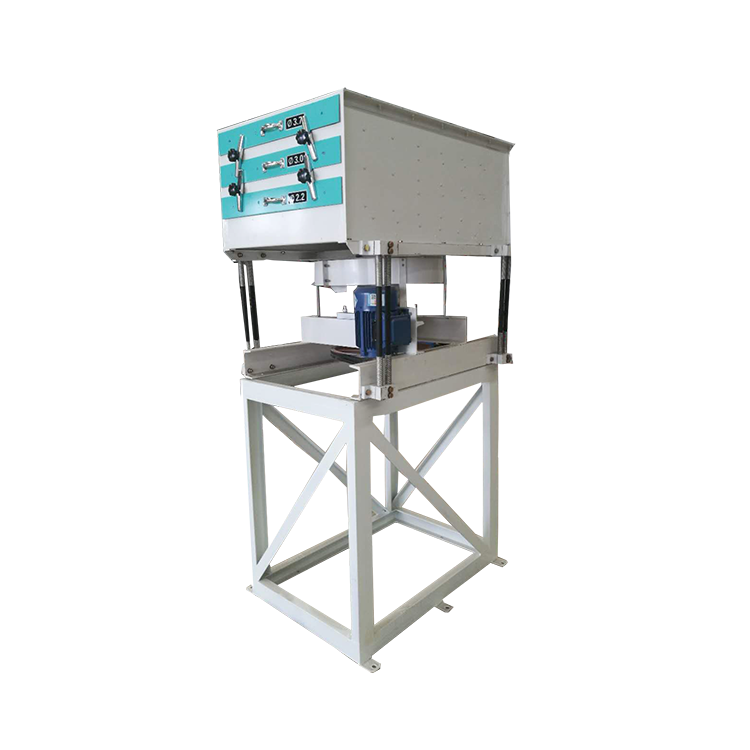

MMJP series flat to white rice grading selection screen, mainly used in rice processing plants for rice grading selection. It takes advantage of individual differences in whole rice grains. Overlapping rotation is made on the screen surface of plane rotation, and friction propulsion forms automatic classification. After proper continuous screening with screen surface, broken rice and whole rice are separated. The equipment has compact structure, stable operation, good process performance and simple operation.

Operation video

Maintenance video

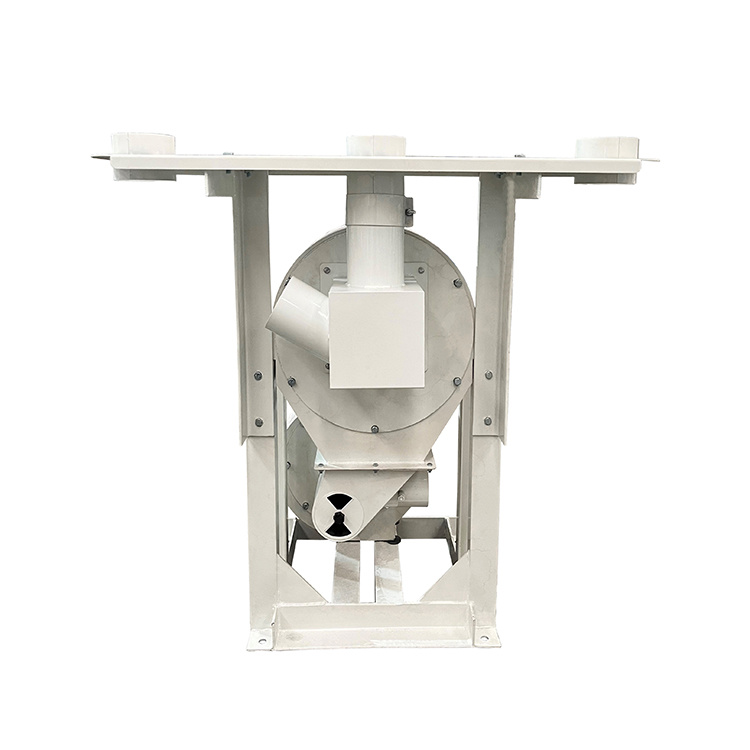

Drum type cleaning stone removal machine

When the machine is working, the raw grain is naturally fed from the inlet of the circular sieve. As the circular sieve runs at low speed and matches the corresponding circular sieve pieces, the rice enters the field sieve from the sieve holes to remove circular sundries twice, and finally enters the fish scale sieve to the sorting chamber of the specific gravity stone remover. The sundries with a volume larger than the rice are automatically discharged from the miscellaneous outlet. Under the action of specific frequency vibration and mixed airflow, the grains with small specific gravity density are suspended in the upper layer, and the stones with large specific gravity density sink into the bottom layer, contact with the fish scale sieve surface, and the shape separation is automatically discharged from the stone removal port.

Operation video

Maintenance video

By laying a ventilation groove on the silo body that penetrates the wall surface of the silo body, the outer layer of rice grain material and the inner layer of rice grain material in the cavity of the silo body are simultaneously subjected to the action of air flow, forcing heat and excess moisture to be brought out from the silo body to play a cooling role.

Operation video

Maintenance video

According to the conveying speed, the conveying amount can be adjusted, and the lifting height can be selected as required. The hopper is designed and manufactured by our company. According to the on-site working conditions, various materials such as wear resistance and corrosion resistance can be selected. The bucket elevator adopts inflow feeding, induced unloading and large-capacity hopper-intensive arrangement, so that there is little extrusion and collision between raw materials and the scattering of raw materials is reduced. The fully enclosed casing structure is designed without dust.

Operation video

Maintenance video

Ultra low speed anti-crushing elevator

Ultra-low line speed, full gravity unloading, low backflow, no increase in crushing; large output, small footprint using wear-resistant plastic bucket (special for rice) and high-strength bucket belt, strong and durable; easy to disassemble and assemble the upper and lower seats of the machine, safe and reliable;

Operation video

Maintenance video

Bucket elevator is suitable for vertical lifting of paddy, brown rice, rice, wheat, corn and other loose granular materials. The machine can be used with various rice milling equipment, and can be used for various threshing and cleaning, drying, bagging, grain silo and other occasions of lifting work.

Operation video

Maintenance video

DZ series vacuum packaging machine, just press the vacuum chamber cover can complete the whole process of vacuuming or filling inert gas sealing, printing, cooling and exhaust after vacuuming according to the set procedure. After vacuum or vacuum inflatable packaging items can prevent oxidation, mildew, moth, moisture, extend the product storage life.

Operation video

Maintenance video

Language

Language